Printing logo BOPP self adhesive packing tape production line

Self adhesive BOPP packing tape production line can produce different sizes of clear tapes, printed tapes and color tapes with good quality.

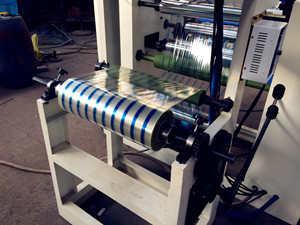

Coating & Gravure printing:

Correction device & Four shafts slitting:

Technical parameters of the self adhesive BOPP packing tape production line:

|

Coating width |

500mm, 1000mm |

Temperature control |

Max 120℃ |

|

Coating method |

Comma blade,transfer coating |

Rewinding edge flatness |

Error≤1mm |

|

Max unwinding diameter |

600mm |

Printing working width |

500mm, 1000mm |

|

Max rewinding diameter |

200mm |

Power loading |

15kw |

|

Mini rewinding width |

1 inch |

framework |

12# square steel tube |

|

Drying method |

Inbuilt water tank heated by electricity |

Coating speed |

0-40m/min |

Raw material:

Production process of the self adhesive BOPP packing tape production line:

Before we start the production, we need to cut the long paper core to suitable width with the paper core cutter, then we use the paper core loader to make the small paper tubes attached on the slitting shaft.

1. set the OPP film on the raw material shaft.

2. print on the film(or you don’t print).

3. glue the film.

4. dry the glue through the oven.

Finally, slit the film into small tapes or make the film into a jumbo roll.

To get a complete system, maybe you will also need other three machine: core loader, core cutter and rewinder.

The final BOPP carton sealing tape: